Micro-Moulding? Big Solution

einsdev2023-02-24T14:48:09+01:00Anybody who has ever had to devise or design an End-of-Arm-Tooling certainly knows that the smallest details are often the most stimulating challenges to win, in order to create a flawless solution. This is especially true when it comes to “micro-moulding”.

Micro-moulding is a highly specialised moulding process, which produces extremely small thermoplastic components with micron tolerances and with weights lower than a gram. This sort of application must be able to mould thousands of identical components in a very short lapse of time. This is where EINS plays a leading role, with its dedicated range of EOAT's components.

Our multi-ejectors can hold micro-moulded components, avoiding thus that they fall from the mould, thanks to their outstanding suction power, up to 700 litres/minute!

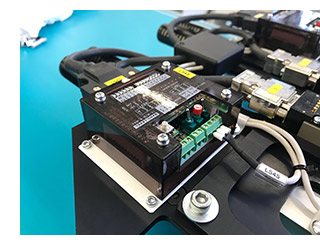

But how can you be sure that such tiny parts have been properly gripped, as they are often so small and difficult to detect? No problem at all, if EINS is by your side! Our range boasts the unbeatable B-SENS-UNIT sensor. Don’t be fooled by its size! Despite its 8 millimeters, it can sense with absolute certainty the presence of the moulded part and give a signal to its counterpart, the B-COUNT-UNIT control. One single board can detect up to 32 points, either with AND or OR outputs, depending on your needs.

Click here to watch the video about the micro-moulding components!

For any further information feel free to contact us: your EINS team will be happy to help you and suggest the best solution for all your requests.

Leave a Reply