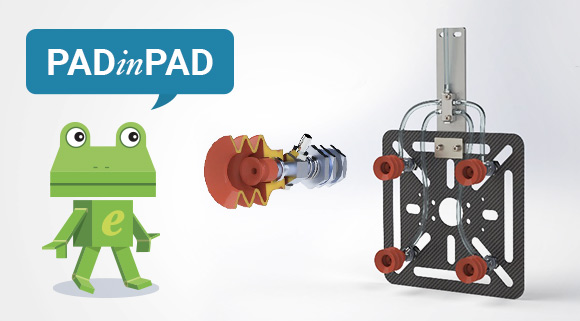

Pad in Pad: A fast solution for a common problem!

einsdev2023-02-24T14:49:16+01:00Have you ever had to mould or handle pierced products and not know what to assemble on your EOAT to solve this problem? No problem at all! Our “Pad in Pad” suction system is the solution you are looking for when moulding pierced products: food containers, caps and inner stoppers of cosmetic products, small gears, metal nuts, etc.

Composed of an outside bellows cup, suction metal fixture, tamping cup and middle hardware, the flat face of the product is absorbed with the outside bellows pad.

Holes are then stopped thanks to the inner tamping pad. Here is a video

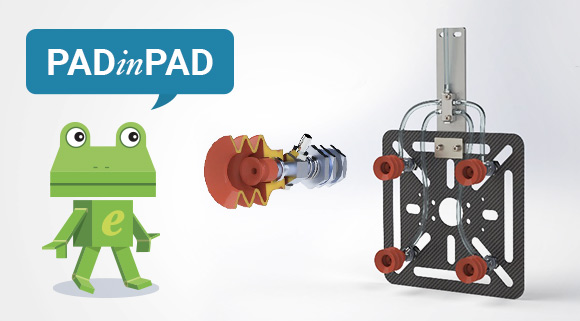

Thanks to an EOAT equipped with four Pad in Pad systems, one of our customers has managed to take out 4 pierced plastic bushings with an Sp-600F IV sprue picker.

The carbon fibre EOAT makes the chuck plate very light (it only weighs 180 grams!); moreover, it is possible to adjust the position of its suction cups and use it with different moulds.

The Pad in Pad system prevents dust and stains deriving from automatic drop from the mould and reduces inspection times: in fact, only sampling inspection is sufficient.

Visit our dedicated page and browse through all the different items; we recommend you to try our TEST KIT, which is available at a very special price of 119.90 € only until December 7th!

Leave a Reply